If you're interested in purchasing custom boots, please don't hesitate to contact us at orders@bont.com, and we'll provide you with information about the nearest molding agent.

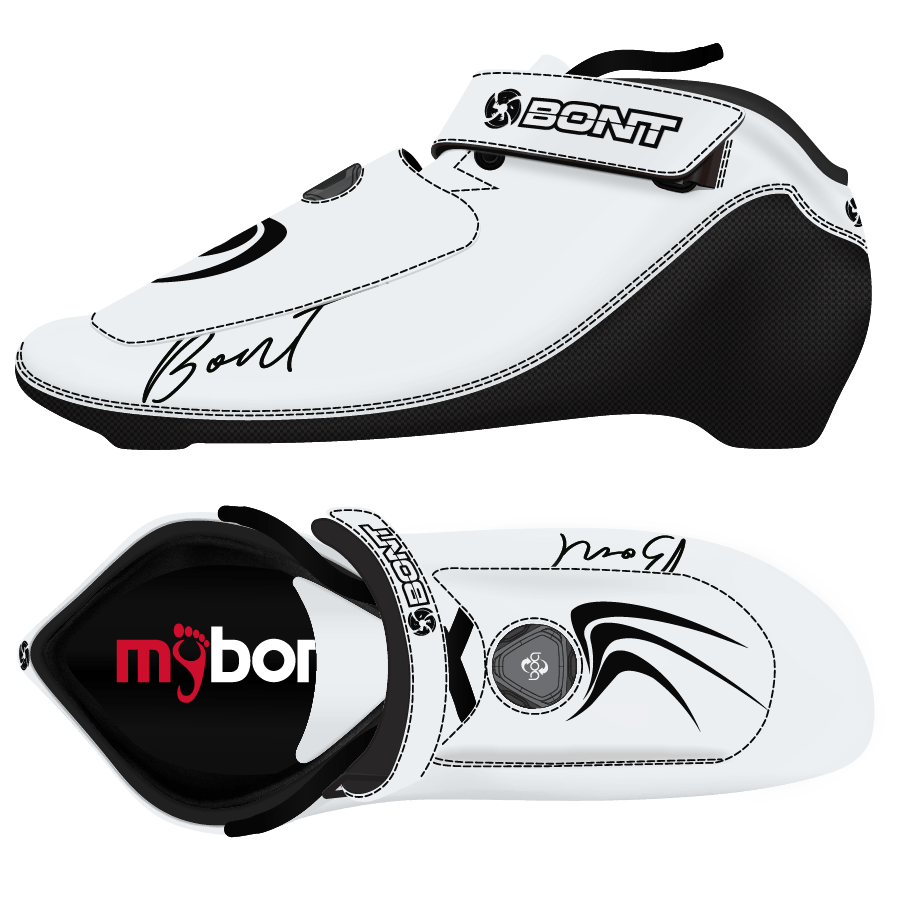

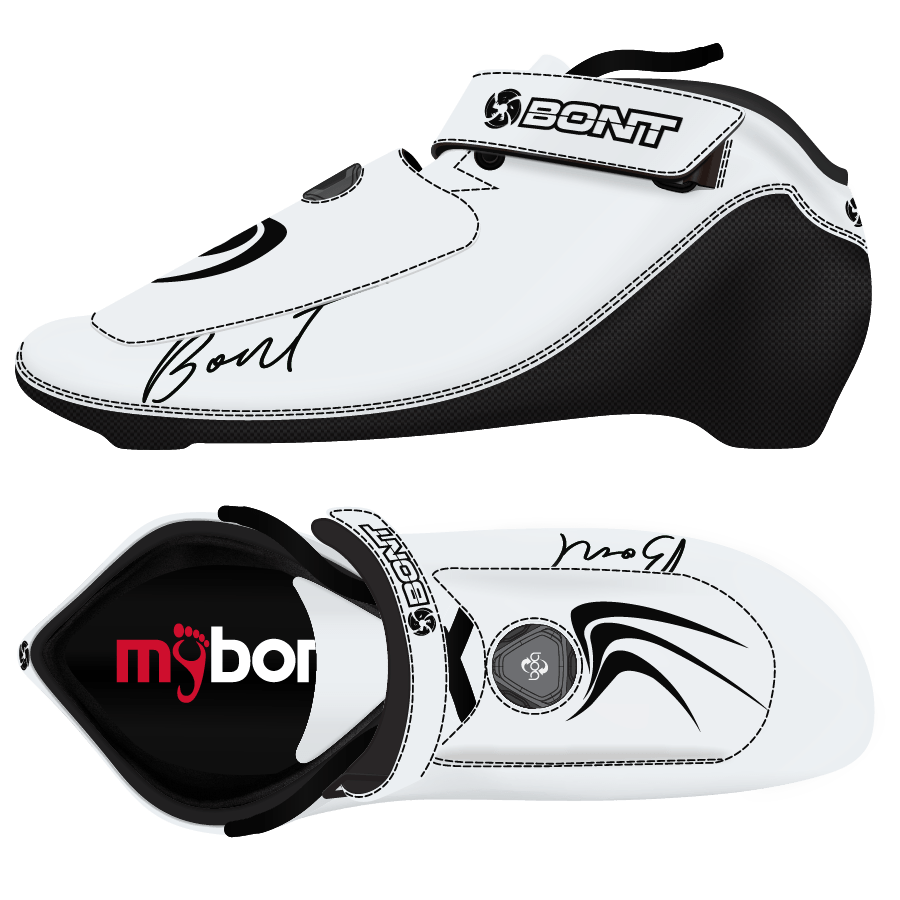

Discover the Ultimate in Short Track Skating with Bont's Custom BNT Short Track Speed Skating Boots

Bont Skates, the pioneer of custom-made inline and roller skates since 1974, proudly presents the custom-made version of the BNT short track speed skating boot. Embrace the legacy of innovation with Bont, the company that crafts more custom skates daily than all other custom boot makers combined.

Why Choose Custom?

Custom boots from Bont offer unparalleled fit and comfort. Once you've experienced the perfect alignment and support of our custom short track boots, you'll never settle for stock boots again. Our custom skates are designed to fit the unique contours of your feet, ensuring maximum performance and comfort.

Tailored to Your Needs

Every aspect of the BNT short track skate is customizable, with numerous options available at no extra cost. Whether it's the boot height, tailored to the height of your ankle bone, or the various design elements, we cater to your every need. For those with higher ankles, our boots provide the perfect fit with an appropriately higher cut.

Simple and Easy Process

Getting your custom short track skates is straightforward. Contact us, and we'll guide you to your nearest Bont representative, who will take precise molds of your feet. The crafting of your custom boots commences upon receiving these molds, typically taking 8-12 weeks. Please note it can take 2-3 weeks for us to receive your molds.

The Exceptional BNT: Crafted for Excellence

The BNT showcases the pinnacle of Bont's expertise in short track skate design. This boot features a timeless style with clean, simple lines that exemplify our commitment to straightforward performance and aesthetics. The core of the BNT is composed of 100% carbon fiber, symbolizing Bont's forward-thinking in short track skate technology. This base, combined with our signature epoxy resin, is heat-moldable for a snug fit. The neoprene padding, a type of closed-cell foam, doesn't absorb water, ensuring the boot remains lightweight and effective.

Join the Custom Revolution

Step into the world of custom short track skates and experience the difference. With Bont's custom-made BNT boots, your short track skating will reach new heights of performance and comfort. Order now and transform your skating experience.

Please note the colors displayed on your screen are a close representation of what your product will look like. We have tried to make this representation as close as possible but the finished product may look slightly different from what you see on the screen. The texture of the material may also differ.

Carbon Fiber

Carbon fiber (or carbon fibre, depending on US or UK spelling) is an advanced composite material known for its exceptional strength-to-weight ratio. It is as strong as steel while weighing only a fraction as much.

Carbon fiber is made from bonded carbon atoms aligned along the length of each fiber. Thousands of these fibers are twisted into a yarn, which is then woven into fabric. This fabric forms the carbon sheets used in high-performance products.

Bont has been producing carbon-based boots since 1989. We source our carbon exclusively from Toray in Japan, the world leader in carbon fiber manufacturing.

Types of Carbon We Use

3K PLAIN

A tightly woven carbon commonly used in the aircraft industry and throughout Bont boots. Strong, reliable, and ideal for structural applications.

UNIDIRECTIONAL

Extremely stiff, lightweight carbon with fibers running in a single direction. This lets us place the carbon exactly where strength and support are needed. Used in our highest-performance boots, such as the Vaypor.

12K PLAIN

A larger weave that is more economical but not as strong as 3K. It reduces cost while maintaining adequate performance in less demanding applications.

INDUSTRY MISREPRESENTATION

Modern composites can be confusing, and not every product marketed as “carbon” contains true carbon fiber construction. Here are common examples of misleading terminology in the industry:

Single-Layer Carbon

Some boots have a plastic, nylon or fiberglass base covered with only one cosmetic layer of carbon. Although they can legally say “carbon base,” the structure underneath is not full carbon.

Unidirectional Carbon (Misused)

Some brands add carbon particles into plastic and call it “unidirectional carbon.” True UD carbon refers to continuous fibers all running in the same direction, not carbon-filled plastic.

Silver Fiberglass

A plastic base with carbon particles is often wrapped with silver fiberglass, then marketed as “carbon fiber.” Real carbon fiber fabric is always black.

100% Composite

A vague term that can mean almost anything. In most cases, it refers to a nylon–fiberglass composite, not a full carbon construction.

Monocoque (Misused)

A true monocoque boot has carbon laminated directly onto the liner, forming a one-piece shell. Some brands use the term incorrectly for shells with an integrated heel cup.

In Summary

Carbon terminology can be misused, so it helps to understand what you are buying. Bont uses genuine carbon fiber from Toray and builds boots with transparent, proven construction methods. Knowing the differences ensures you get the performance, strength, and value you expect from a true carbon boot.

Manufacturing Process

Bont is one of the few skate brands that still handcrafts boots using an inside-out manufacturing method. This approach is far more skill-intensive and time-consuming than mainstream production, but it allows us to create boots with the performance, strength and responsiveness skaters expect. While it increases production costs, it delivers a lighter and more precise final product.

We continually refine our processes to maintain the highest quality. For example, traditional vacuum curing for carbon has been replaced with pressure wrapping, which applies four atmospheres of pressure instead of one. This produces a more consistent and durable carbon layup.

Inze Bont’s engineering innovations have helped optimize our production line so we can build handmade monocoque boots efficiently without compromising craftsmanship.

Our manufacturing methods reflect our performance philosophy: lighter, stronger and faster.

For more detail on individual components of our construction, explore the technical dropdowns on this page, including Last Design, Footbed, Liner, Anti-Stretch, Carbon Fiber, Upper and more.